AGV Special planetary reducer

With the goal of opening up new markets in the field of logistics, we are continuously improving the performance of AGVs

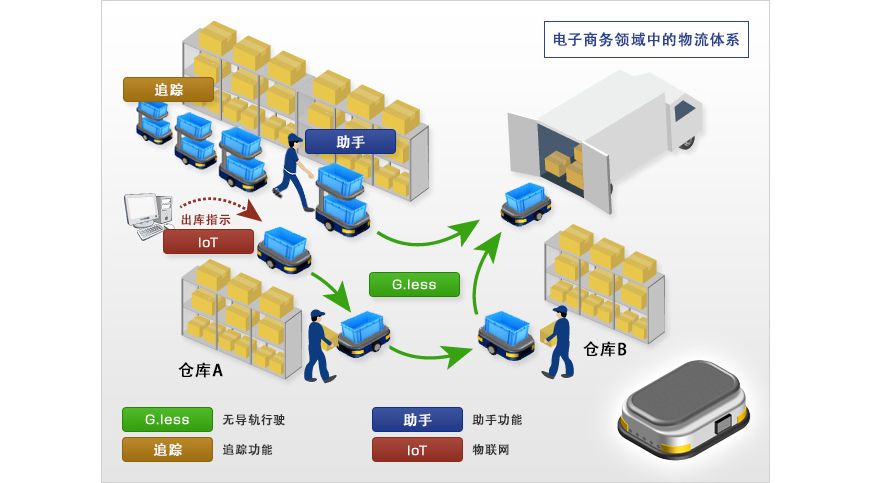

AGVs (Automated Guided Vehicles), which are currently active in various production lines, are expected to shine in the logistics field, where there is a lot of room for growth. Distribution centers dedicated to convenience stores and distribution centers dedicated to online shopping are still the mainstream of high-frequency delivery systems, but on the other hand, the market demand for AGVs is expanding due to the high labor costs and the increasing difficulty in securing personnel. Unlike the specifications required by the production line so far, the requirements for AGVs in the logistics and warehousing field are smaller, quieter, and no guides. Unlike AGVs, which were originally used in the production line on the premise of calculating the weight of goods in tons, AGVs used in the field of logistics and warehousing are used to carry goods instead of people, and the weight of goods is tens of kilograms. In addition, since it is working in a warehouse, it is required to be quieter than in the production line. In addition, in the case of replacing people, instead of simply attaching a magnetic strip to the floor to make it function as a guide, LiDAR and image recognition technology are used to remove obstacles and move freely in the warehouse with simple instructions.

Not only parts but also components can be supplied

On the demand side of the warehouse, the Japan Densho Group continues to improve its system and integrate resources such as brushless DC motors, high-precision reducers, and sensors to provide not only components to customers, but also component-based products such as drive units. In particular, the production resources such as brushless DC motors and precision reducers are the world's leading high-tech products, and their competitiveness is also very huge. In addition, the development of a new type of AGV called smartAGV is also underway. In addition to driving without guides, these smartAGVs have IoT functions such as a tracking function that allows you to drive in a queue without a physical connection, an assist function to assist human activities, a fault prediction based on vibration and noise data from each part, and an effective operation plan for the collection and analysis of location and driving data. If the quietness performance can be further improved, AGVs can also be used in medical institutions, art galleries, museums and other places, and their potential market demand will be further expanded.

AGVs (Automated Guided Vehicles), which are currently active in various production lines, are expected to shine in the logistics field, where there is a lot of room for growth. Distribution centers dedicated to convenience stores and distribution centers dedicated to online shopping are still the mainstream of high-frequency delivery systems, but on the other hand, the market demand for AGVs is expanding due to the high labor costs and the increasing difficulty in securing personnel. Unlike the specifications required by the production line so far, the requirements for AGVs in the logistics and warehousing field are smaller, quieter, and no guides. Unlike AGVs, which were originally used in the production line on the premise of calculating the weight of goods in tons, AGVs used in the field of logistics and warehousing are used to carry goods instead of people, and the weight of goods is tens of kilograms. In addition, since it is working in a warehouse, it is required to be quieter than in the production line. In addition, in the case of replacing people, instead of simply attaching a magnetic strip to the floor to make it function as a guide, LiDAR and image recognition technology are used to remove obstacles and move freely in the warehouse with simple instructions.

Not only parts but also components can be supplied

On the demand side of the warehouse, the Japan Densho Group continues to improve its system and integrate resources such as brushless DC motors, high-precision reducers, and sensors to provide not only components to customers, but also component-based products such as drive units. In particular, the production resources such as brushless DC motors and precision reducers are the world's leading high-tech products, and their competitiveness is also very huge. In addition, the development of a new type of AGV called smartAGV is also underway. In addition to driving without guides, these smartAGVs have IoT functions such as a tracking function that allows you to drive in a queue without a physical connection, an assist function to assist human activities, a fault prediction based on vibration and noise data from each part, and an effective operation plan for the collection and analysis of location and driving data. If the quietness performance can be further improved, AGVs can also be used in medical institutions, art galleries, museums and other places, and their potential market demand will be further expanded.

Location:

Location:

+86 13812909957

+86 13812909957